As an acrylic manufacturing company, we aim to provide a wide range of material options to suit any project and environment. This also includes working with recyclable substances, such as Green Cast®, to provide a more sustainable option.

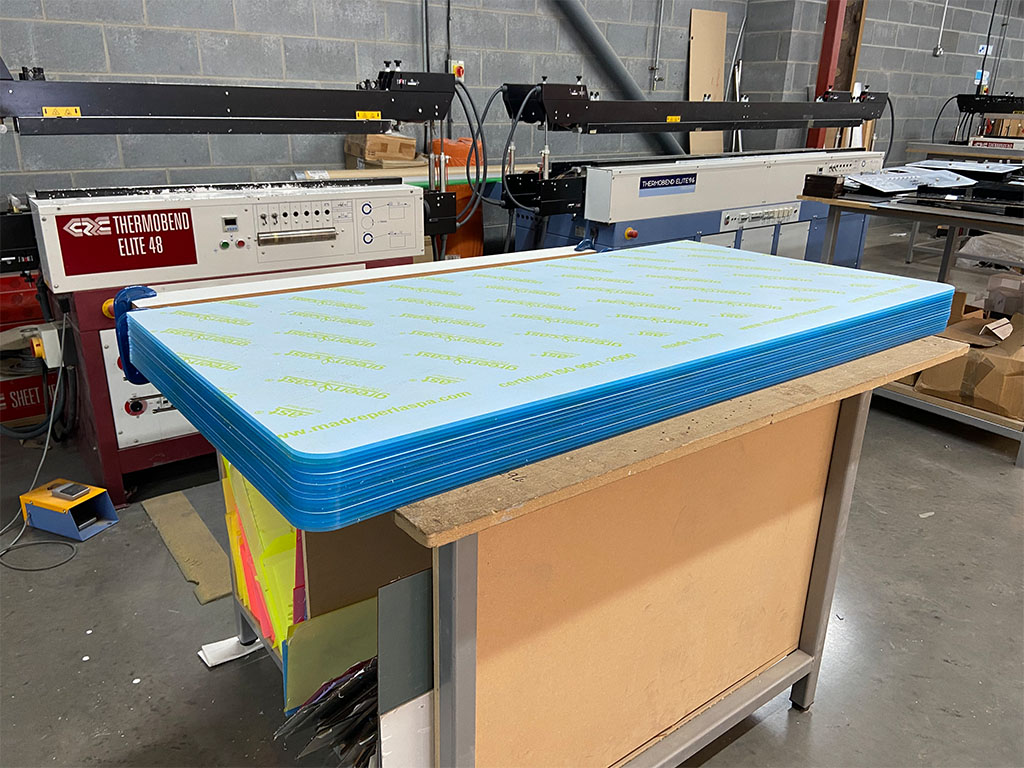

We currently have a project going through our factory for office desk dividers, all created from Green Cast® clear acrylic. The benefit of using this material is that it looks and performs exactly the same as standard acrylic.

The feature of being full recyclable is an added bonus, especially for those trying to reduce their environmental impact. Many companies that are looking to use acrylic, are now pushing to use only recycled material, to create a more eco-friendly project.

Any acrylic material that cannot be reused is transformed back to its original state, then returned to the production process. This creates a cycle of production that uses all of the material and makes for a more sustainable practice.

Ino-Plaz – Innovation in Plastics

Since 2004, Ino-Plaz has grown rapidly in the industry, now at the forefront of bespoke acrylic design and fabrication. Based in Hull, we work alongside industry leaders from a multitude of sectors such as Point of Sale, Shop Fit Supply and Signage. From working with a range of industries, our level of expertise allows us to approach every new challenge head on. Whether the project is a single bespoke installation or a worldwide product rollout. Ino-Plaz apply the same meticulous attention to detail and always flexible to see the project through to completion. In addition, we work closely with clients, walking through every step of the process. From the initial sketches to the final products. The approach inspires the confidence in customers, they are not only receiving quality products, but quality service too.

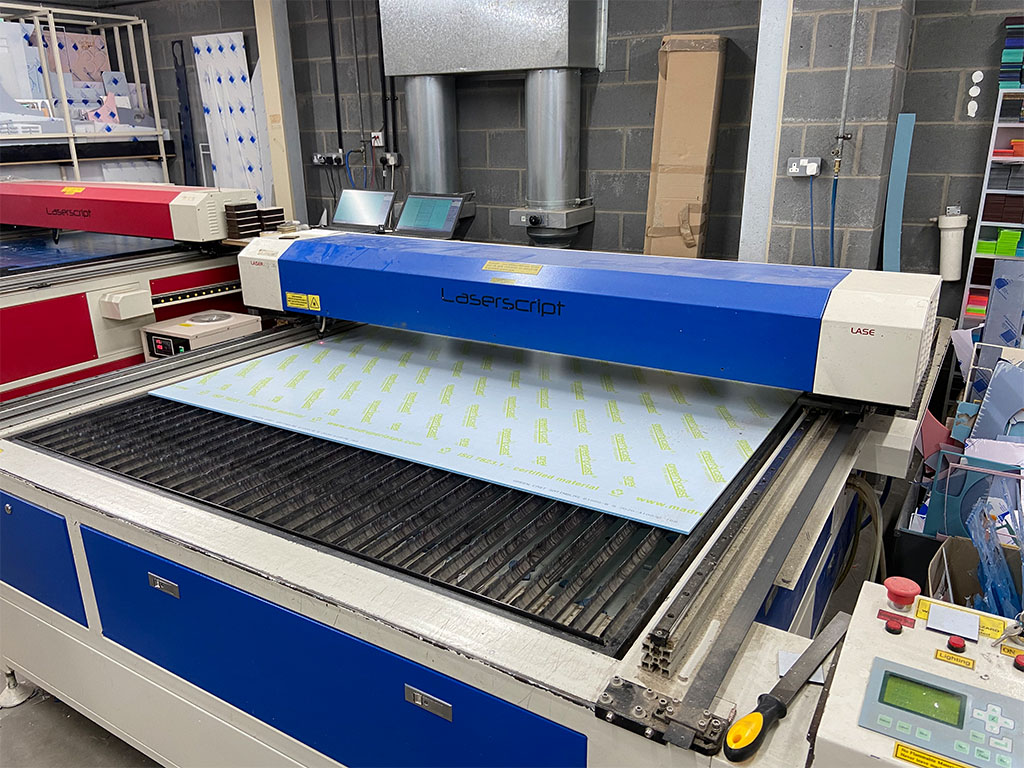

Constantly striving to find new innovative fabrication methods, Ino-Plaz invest in the latest manufacturing technologies. This allows us to provide an ever-growing range of comprehensive fabrication and design services including:

CNC Routing, Drape Forming, CNC Laser, Membrane Press, Line Bending, Machine Routing, Dimond Polishing, Flame Polishing, Buff Polishing, UV Bonding, Dome Blowing, Screen Printing, Digital Flatbed Printing and Bespoke Acrylic Fabrication.

In addition to fabrication and manufacturing services, Ino-Plaz also have an in-house design team. Allowing for full control over the design and makes the process easier as both the designer and fabricator are in one place. The dedicated Graphic Design and CAD specialists use software to create designs and 3D renders of products and ideas. Using this Computer Aided Design improves the quality of the design and creates a database for manufacturing. As well as showing a more realistic 3D representation of the final design.